Introduction

As a chemical process, multicomponent distillation refers to the separation of volatile elements from a mix of their compounds, depending on their boiling points. The distillation column contains stacks of trays upon which the elements coexist in either liquid or vapor levels. As the compound mixture rises up the column, components having relatively lower boiling points get concentrated in the upper stages while those having relatively higher boiling points get concentrated in the lower stages.

Vapor Flow Conditions in Multicomponent Distillation

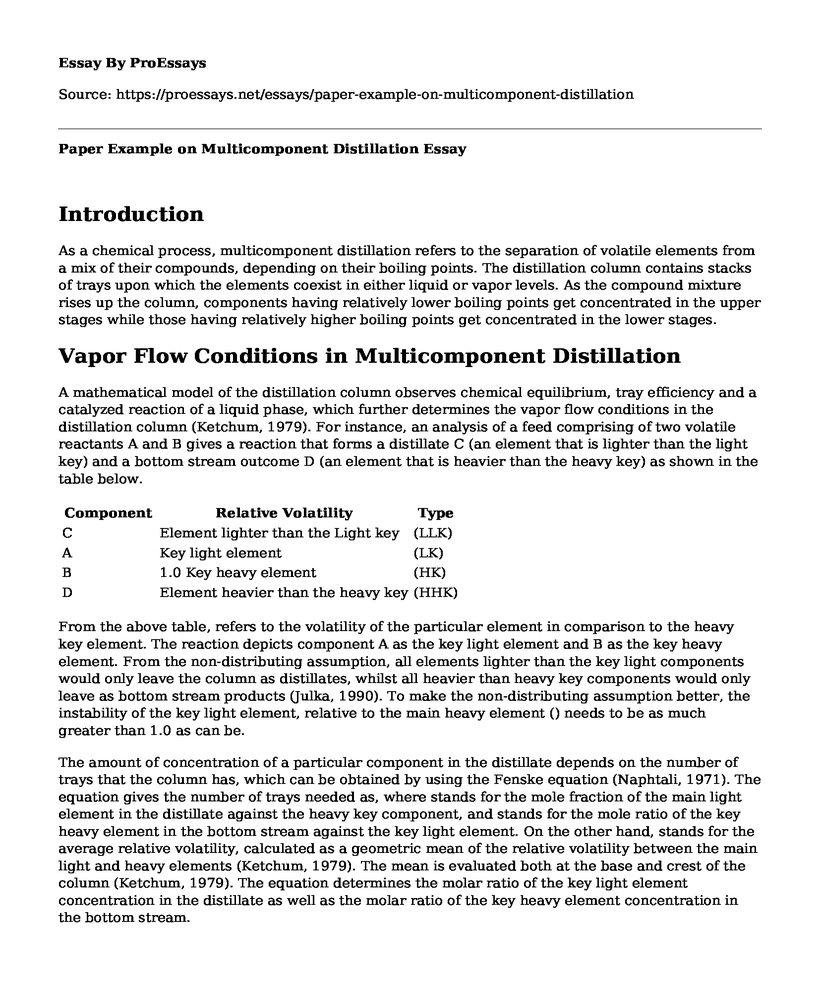

A mathematical model of the distillation column observes chemical equilibrium, tray efficiency and a catalyzed reaction of a liquid phase, which further determines the vapor flow conditions in the distillation column (Ketchum, 1979). For instance, an analysis of a feed comprising of two volatile reactants A and B gives a reaction that forms a distillate C (an element that is lighter than the light key) and a bottom stream outcome D (an element that is heavier than the heavy key) as shown in the table below.

| Component | Relative Volatility | Type |

| C | Element lighter than the Light key | (LLK) |

| A | Key light element | (LK) |

| B | 1.0 Key heavy element | (HK) |

| D | Element heavier than the heavy key | (HHK) |

From the above table, refers to the volatility of the particular element in comparison to the heavy key element. The reaction depicts component A as the key light element and B as the key heavy element. From the non-distributing assumption, all elements lighter than the key light components would only leave the column as distillates, whilst all heavier than heavy key components would only leave as bottom stream products (Julka, 1990). To make the non-distributing assumption better, the instability of the key light element, relative to the main heavy element () needs to be as much greater than 1.0 as can be.

The amount of concentration of a particular component in the distillate depends on the number of trays that the column has, which can be obtained by using the Fenske equation (Naphtali, 1971). The equation gives the number of trays needed as, where stands for the mole fraction of the main light element in the distillate against the heavy key component, and stands for the mole ratio of the key heavy element in the bottom stream against the key light element. On the other hand, stands for the average relative volatility, calculated as a geometric mean of the relative volatility between the main light and heavy elements (Ketchum, 1979). The mean is evaluated both at the base and crest of the column (Ketchum, 1979). The equation determines the molar ratio of the key light element concentration in the distillate as well as the molar ratio of the key heavy element concentration in the bottom stream.

Factors Involved in the Design of Multicomponent Distillation

The design method for multicomponent distillation is often based on stage-to-stage calculations. Most designs that use iterative calculations, initiated with an assumed composition of the distillate as well as the bottoms product, would often lead to wide differences in the profiles per stage composition due to minor variations in the composition. Instead, the proposed design method initiates the iterative process using feed compositions at the feed plate, thereby making it possible to avoid the minor variations.

For the design calculations, the rate of flow, compositions and the value of feed need specification besides the reflux ratio. Additionally, the rate of flow of both the concentrate and the base stream outcome require to be stipulated (Kister, 1992). Further, the fractional recovery of one of the components (the light key element or the heavy key element) requires to be specified either in the bottom stream or in the distillate (Lewis, 1932). Finally, the criterion for introducing the feed also require to be specified. With this proposed design, the specifications of the fractional retrieval of both key light and heavy elements can be utilized in computing the value of the distillate or the bottom stream re (Kister, 1992). However, the recovery of either the light or heavy key components cannot be achieved if a check is not made, that neither the distillate nor the bottom stream product goes above allowable value.

The composition of the bottom stream product can be obtained from the overall material and enthalpy balance around the column, after which stage-to-stage calculations are done from the re-boiler moving upward (Thong, 2001). The stripping section calculations would then be completed when the criteria for feed introduction is met, to complete one iteration process. However, if the fractional recovery of the lightest component exceeds the specified amount, the fractional stage would be found by linearly interpolating the recovery between that of the vapor entering and vapor leaving the column's top stage (Thong, 2001). The mole fractions of other components would then be interpolated continually in the same ratio until a convergence criterion is met, thus keeping the fractional recovery in check (Thong, 2001).

References

Julka, V. a. D. M., 1990. Geometric behavior and minimum flow for nonideal multicomponent distillation. Chemical Engineering Science, 45(7), pp. 1801-1822.

Ketchum, R., 1979. A combined relaxation-Newton method as a new global approach to the computation of thermal separation processes. Chemical Engineering Science, 34(3), pp. 387-395.

Kister, H. H. J. H. D. a. G. D., 1992. Distillation design. 1st ed. New York: McGraw-Hill.

Lewis, W. a. M. G., 1932. Studies in distillation. Industrial & Engineering Chemistry, 24(5), pp. 494-498.

Naphtali, L. a. S. D., 1971. Multicomponent separation calculations by linearization. AIChE Journal, 17(1), pp. 148-153.

Thong, D. A. K. S. R. a. T. G., 2001. Design and optimization of fully thermally coupled distillation columns: Part 1: Preliminary design and optimization methodology. Chemical Engineering Research and Design, 79(7), pp. 701-715.

Cite this page

Paper Example on Multicomponent Distillation. (2022, Jul 29). Retrieved from https://proessays.net/essays/paper-example-on-multicomponent-distillation

If you are the original author of this essay and no longer wish to have it published on the ProEssays website, please click below to request its removal:

- Impacts of Geography and Culture on the Development of Economy and Business in North America in the 18-19th Centuries

- Research Paper: Sectoral and Economic Growth in Serbia

- Questions and Answers on Functions Paper Example

- Nature of Magnetic Surfactants Essay Example

- The History of the Discovery of Dark Energy Essay Example

- Essay on Exploring the Moon: The Emergence of Selenology and Selenography

- Stars: Life Cycles, Bangs, and Supernovas - Essay Sample