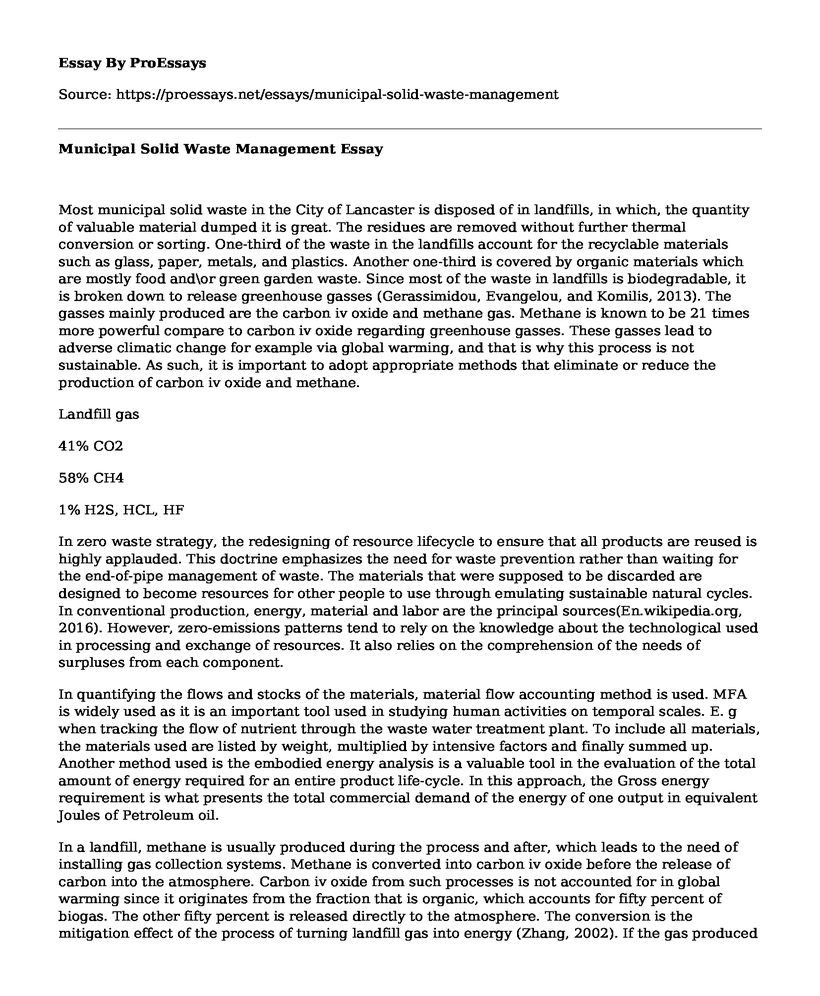

Most municipal solid waste in the City of Lancaster is disposed of in landfills, in which, the quantity of valuable material dumped it is great. The residues are removed without further thermal conversion or sorting. One-third of the waste in the landfills account for the recyclable materials such as glass, paper, metals, and plastics. Another one-third is covered by organic materials which are mostly food and\or green garden waste. Since most of the waste in landfills is biodegradable, it is broken down to release greenhouse gasses (Gerassimidou, Evangelou, and Komilis, 2013). The gasses mainly produced are the carbon iv oxide and methane gas. Methane is known to be 21 times more powerful compare to carbon iv oxide regarding greenhouse gasses. These gasses lead to adverse climatic change for example via global warming, and that is why this process is not sustainable. As such, it is important to adopt appropriate methods that eliminate or reduce the production of carbon iv oxide and methane.

Landfill gas

41% CO2

58% CH4

1% H2S, HCL, HF

In zero waste strategy, the redesigning of resource lifecycle to ensure that all products are reused is highly applauded. This doctrine emphasizes the need for waste prevention rather than waiting for the end-of-pipe management of waste. The materials that were supposed to be discarded are designed to become resources for other people to use through emulating sustainable natural cycles. In conventional production, energy, material and labor are the principal sources(En.wikipedia.org, 2016). However, zero-emissions patterns tend to rely on the knowledge about the technological used in processing and exchange of resources. It also relies on the comprehension of the needs of surpluses from each component.

In quantifying the flows and stocks of the materials, material flow accounting method is used. MFA is widely used as it is an important tool used in studying human activities on temporal scales. E. g when tracking the flow of nutrient through the waste water treatment plant. To include all materials, the materials used are listed by weight, multiplied by intensive factors and finally summed up. Another method used is the embodied energy analysis is a valuable tool in the evaluation of the total amount of energy required for an entire product life-cycle. In this approach, the Gross energy requirement is what presents the total commercial demand of the energy of one output in equivalent Joules of Petroleum oil.

In a landfill, methane is usually produced during the process and after, which leads to the need of installing gas collection systems. Methane is converted into carbon iv oxide before the release of carbon into the atmosphere. Carbon iv oxide from such processes is not accounted for in global warming since it originates from the fraction that is organic, which accounts for fifty percent of biogas. The other fifty percent is released directly to the atmosphere. The conversion is the mitigation effect of the process of turning landfill gas into energy (Zhang, 2002). If the gas produced is not removed, then there is likely to be a rise in safety hazards such as spontaneous combustion, leak into the nearby buildings or cause damage to the lining.

To dispose of one gram of waste, 0.3 grams of further materials is essential. To produce at least one kWh of electric energy, 334 g of the abiotic matter is needed, which is concerned with intensities of materials for electricity production. In both forward and reverse logistics, the content in the chain go in a final way, that is, they interact with each other. The grave of the lifecycle of a product is the beginning of reverse logistics (Pochampally, Nukala, and Gupta, 2009). Conducting testability at all levels within reverse logistics is important. The testability decides when the products are recovered where the product is required to re-enter to forward logistics.

Waste hierarchy

1 Prevention 2 Reuse 3 Recycling

4 Recycling

5 Disposal

To effectively manage waste, it is important to use the waste hierarchy principle that has been tested and is widely applied in the world. Waste hierarchy is essential to sustainable management of waste and a legal requirement that all organizations should follow to manage their waste. The hierarchy's top priority is waste prevention, reuse follows, recycling then recovery and finally the disposal. Prevention aims at reducing the amounts of hazardous products by modifying the industrial production(Anon, 2016). To promote reuse, recovery, and recycling, there should be an increase in the incentives. Reuse and Recycling ensure that a product that would have been otherwise disposed of is used for another purpose. Recycling and reuse help reduce the amount waste roaming around. For waste that has not been prevented or recovered, it is finally disposed of to the respective place. Recycling is by far the most efficient and doable practice among the rest.

Life cycle analysis is an approach that evaluates the impacts of the environment that related to all stages of products life from its beginning to the end. The life cycle consists of several stages: extraction of materials, processing, and manufacturing, product use and finally disposal of product(Singh, Pant, and Olsen, n.d.). The life cycle analysis has four variants namely; cradle- to- grave, cradle- to- cradle, well- to -wheel, and cradle to gate. Cradle to grave is the optimum life cycle estimation from the extraction of the resource, use phase and finally disposal phase. In all the stages of a resource life cycle, all inputs and outputs are considered.

Cradle-to-grave

Cradle-to-cradle

Cradle to cradle is a type of cradle to grave evaluation in which the final stage which is disposal is a recycling process. This method aims at reducing hazards to the environment by using practices that are sustainable (Braungart, McDonough, and Bollinger, 2007). Cradle to cradle provides identical products or different products from the already used resources by recycling. With this concept, the end of one product signifies the beginning of another product.

Well-to-wheel

Well to wheel is the precise life cycle analysis whose purpose is for transport fuels and vehicles. Well to wheel is divided into stages; well-to-station or well to tank and tank-to-wheel or station-to-wheel. The upstream stage is the first stage, in which feedstock, processing and fuel delivery is incorporated. The stage that is responsible for vehicle operation itself is called the downstream stage. Well-to-wheel is in charge of calculating the total energy use, petroleum use, fossil energy consumption including the emissions and the pollutions at each stage.

Cradle-to-gate

Cradle to the gate only analyses the product life partially; that is from its manufacture to just before the consumer gets to own it. The analysis allows collecting the impacts that lead to the purchase of the resource by the facility.

For energy conversion factors, the following formula is used;

Carbon footprint (kgCO2e per unit)= activity data (per unit) * emission factor (kgCO2e)

References

Anon, (2016). [online] Available at: http://www.lancashire.gov.uk/media/347661/wmstrategy-1-.pdf [Accessed 1 Dec. 2016].

Anon, (2016). [online] Available at: https://www.milton-keynes.gov.uk/assets/attach/4164/7(5).pdf [Accessed 1 Dec. 2016].

Braungart, M., McDonough, W. and Bollinger, A. (2007). Cradle-to-cradle design: creating healthy emissions a strategy for eco-effective product and system design. Journal of Cleaner Production, 15(13-14), pp.1337-1348.En.wikipedia.org. (2016). Zero waste. [online] Available at: https://en.wikipedia.org/wiki/Zero_waste [Accessed 1 Dec. 2016].

Gerassimidou, S., Evangelou, A. and Komilis, D. (2013). Aerobic biological pretreatment of municipal solid waste with a high content of putrescible: effect on landfill emissions. Waste Management & Research, 31(8), pp.783-791.

Jensen, A. (1998). Life cycle assessment (LCA). 1st ed. Copenhagen, Denmark: European Environment Agency.

McDonough, W. and Braungart, M. (2002). Cradle to cradle. 1st ed. New York: North Point Press.

Pochampally, K., Nukala, S. and Gupta, S. (2009). Strategic planning models for reverse and closed-loop supply chains. 1st ed. Boca Raton: CRC Press/Taylor & Francis.

Singh, A., Pant, D. and Olsen, S. (n.d.). Life cycle assessment of renewable energy sources. 1st ed.

Zhang, X. (2002). EVALUATION OF TECHNOLOGIC DYNAMIC CHARACTERISTIC OF CO2 ARC WELDING POWER SOURCE BASING ON WAVELET ANALYSIS. Chinese Journal of Mechanical Engineering, 38(01), p.112.

Cite this page

Municipal Solid Waste Management. (2021, Mar 04). Retrieved from https://proessays.net/essays/municipal-solid-waste-management

If you are the original author of this essay and no longer wish to have it published on the ProEssays website, please click below to request its removal:

- Why We Need the Police in the Society

- Yarnell Hill Fire Essay Example

- Earthquake in Nepal and Its Aftermath Essay

- Training in San Jose Police Department Paper Example

- Essay on Growth of Private Businesses: Profitable Opportunities & Carbon Footprints

- Pacific Railway Act Signed into Law: Transcontinental Railroad Construction Funded - Essay Sample

- Paper on Examining the Environmental Impact of Plastic and Metal Bottles: A Global Economic Perspective